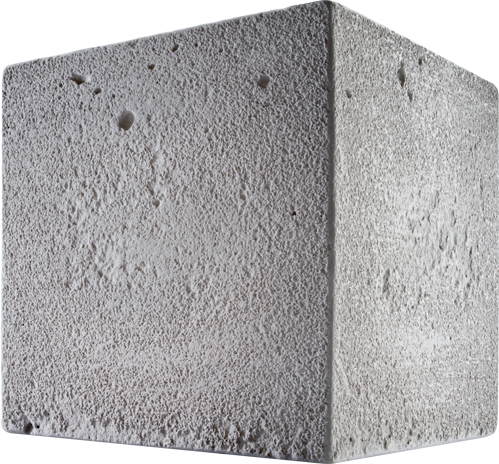

Foam Concrete

– Rediscover Concrete

Specialized building material Quick construction, strong foundation, ground stabilization, energy savings.

Quick

construction

Strong

foundation

Ground

stabilization

Energy

savings

Non-combustibility

Frost

resistance

Thermal

insulation

Durability

Foam Concrete is cast cellular Concrete, i.e. cement material with introduced foam which captures air bubbles in the resulting mass.

Foam Concrete is not sold in blocks, but produced and poured directly on the construction site… 50 m³/h speed and ease of construction

completed projects

in the Polish construction market

speed

and ease of installation

annually worldwide

Looking for a reliable construction material? Foam Concrete WAJM is a modern and eco-friendly solution for the subbase of floors, roads, parking lots, ceilings, and roofs, as well as for ground reinforcement. The cost of foam concrete per m² is similar to traditional building materials, but the benefits make it a worthwhile investment in your time and resources.

Why do investors choose foam concrete?

Foam concrete is several times lighter than standard concrete because the mechanically introduced foam in the mass causes the closure of air bubbles. Foam concrete is chosen not only for its lightness but also for other unique characteristics:

- Fluid consistency — ensures tight coverage of floor surfaces and fills gaps well.

- Low density from 400 to 1400 kg/m³ — reduces the load on the building or foundation.

- Self-leveling — spreads evenly over the surface, even when laid on an uneven substrate. Using lightweight concrete allows you to forgo styrofoam and other materials that have significant drawbacks. Issues such as pest infestations, thermal bridges, and floor settling will no longer be a problem.

Key Features

Cellular concrete is environmentally friendly. Its main component is air, eliminating the need to extract gravel, rubble, and sand, which are becoming increasingly problematic to obtain. Foam Concrete itself contains environmentally friendly components that are safe for humans, and it can be 100% recycled. The main advantages of Foam Concrete:

- Ease of construction — it can be processed with available concrete tools such as saws, chisels, or drills;

- Speed of implementation — up to 100 m³ per hour, which is 5000 m² per day!;

- Labor cost savings — Foam Concrete does not require expensive, heavy equipment and a large number of workers.

Considering the time and amount of resources involved, using Foam Concrete will cost less than traditional solutions.

Where can foam concrete be used?

The technology of foam concrete is widely used in the United States and Canada, China and India, as well as European countries. In the Netherlands, where the ground is mainly weak, it is actually the primary building material. In Poland, lightweight concrete has proven effective in many design solutions in the construction of:

- Foundation slabs;

- Warm industrial floors;

- Roads, bridges, and pedestrian-cyclist paths;

- Parking lots and squares;

- Ceilings and roofs;

- Filling inactive installations and relining.

Cellular concrete is excellent for constructing houses and other structures requiring a stable foundation. It is also ideal for filling underground voids, reinforcing ground in wetlands, and preventing landslides.

Why order from us?

We are the only company in Poland with the technology for continuous production of Foam Concrete with a capacity of up to 50 m³/h, and with the full engagement of our machinery park, even up to 100 m³/h.

We ensure consistent and reliable parameters of Foam Concrete from the first to the last cubic meter, along with the best technical specifications of the produced material.

We produce Foam Concrete with densities from 400 kg/m³ to 1400 kg/m³, compressive strength from 1 to 10 MPa, and thermal conductivity λ starting from 0.05 W/mK.

We produce genuine Foam Concrete – a cementitious material with closed pores and water absorption similar to normal concrete.

Our Foam Concrete does not require expansion joints, does not swell, and is not a result of a chemical reaction. It is also completely eco-friendly and safe for the environment.

We use Dutch machinery and foaming agents.

We have been producing Foam Concrete for over 30 years and have completed over 5000 projects on leading investments in Poland.

We invite you to watch a video of one of our recent projects: https://youtu.be/MDb4JSekxzo

The price of Foam Concrete starts at 499 PLN per m³ and depends on the surface area, local mortar prices, and the quantity and density of the material itself.

Do you have any questions? Contact us — we will provide details about our offer and calculate the cost for your project.

Cinema City

Renovation of a multi-story parking structure due to ongoing structural deterioration. The renovation involved replacing the concrete with PB 600 Foam Concrete. The structure’s levels were relie...

IKEA

Extension of the ceilings of the underground parking lot (second level of the parking lot), where a new hall, a utility road for delivery vehicles, and a parking lot for cars were created. PB 500 Foam...

Galeria Malta

Filling the load-bearing structures with regular concrete led to excessive settling of the structure. 5400 m² of the parking subbase was filled with PB 600 Foam Concrete, reducing the load by over 300...

Poznań – City Fire Department

Filling the ceiling structures, on which fire trucks operate, with PB 500 Foam Concrete. The Foam Concrete was covered with a 2x heat-welded membrane, and a 6 cm paver surface was laid on a sand-cemen...

Leningrad-type Residential Blocks

These buildings were erected economically without roof insulation. Low spaces and firewalls prevented access and the use of commonly used insulation materials. A grid of holes was drilled in the roof,...

Legnica – Knight Academy

These buildings were erected economically without roof insulation. Low spaces and firewalls prevented access and the use of commonly used insulation materials. A grid of holes was drilled in the roof,...